Overview

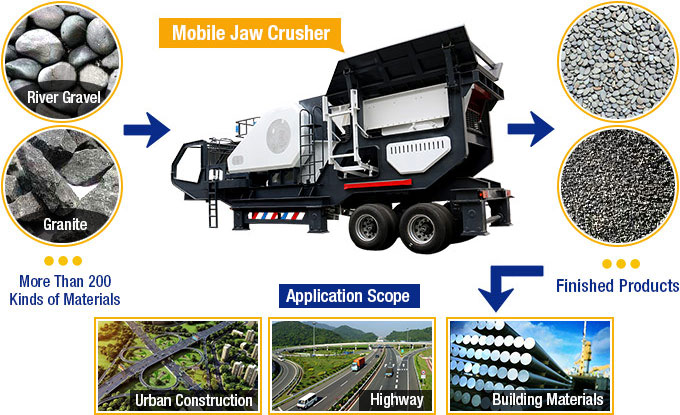

Wheel mobile jaw crusher is also known as mobile jaw crushing plant or removable mobile jaw crusher. Mobile jaw crushing plant is one of the newest rock-crushing equipment, mainly used in metallurgy, chemical industry, building materials, water and electricity industries. The user can use a variety of different configurations according to the material type, size and product material requirements using a variety of different configurations.

1. Widely used in mining, coal mining, garbage and recycling of construction waste, earth works and urban infrastructure, roads or building sites and other ground operations.

2. Handling of topsoil and a variety of other materials; solated viscous concrete aggregate; Construction and demolition industries; Broken screen; Quarrying industry.

3. River pebbles, rocks (limestone, granite, basalt, diabase, andesite), ore tailings and the artificial sand stone chips.

Features

1. The mobile jaw crusher station has short production line, various broken equipment installed on separate removable chassis, short wheelbase, small turning radius, can be flexible on ordinary roads and fields.

2. Reduce the cost of transportation, in the face of processed material, it should not be moved from on-site reprocessing of materials, greatly reducing the shipping cost for the item.

3. The combination is flexible, large adaptability. The crushing process according to different requirements of 'broken screen', also composed 'screening before they are broken' process, according to actual needs into coarse and fine crushing two-stage crushing and screening systems, can also be broken into coarse, medium and fine crushing three stage crushing and screening system, you can also run independently, there is a great deal of flexibility.

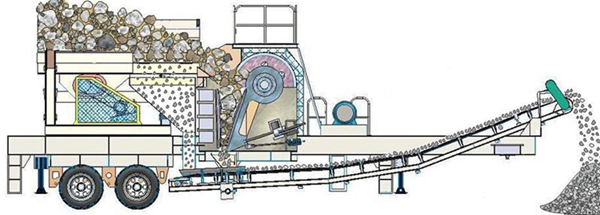

Working Principle:

The material enters into the crusher cavity evenly through the feeding machine. After the primary crushing, closed-circuit system is formed through circular vibrating screen, loop break achieved, finished items output by the conveyor, continuous shredder. Mobile jaw crushing plant can produce according to actual need to remove circular vibrating screen, realizing preliminary crushing of materials directly, use with other broken equipment easy and flexible.

Parameter

| Model | FTM938HD86 | FTM1149HD98 | FTM1349HD110 | FTM1349HD125 |

| Transportation lenght(mm) | 12600 | 13500 | 14500 | 15200 |

| Transportation Width(mm) | 2600 | 2700 | 2800 | 2900 |

| Transportation Height(mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum Lenght(mm) | 12500 | 14000 | 16100 | 16700 |

| Maximum Width(mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum Height(mm) | 4100 | 4900 | 5000 | 5300 |

| Weight(t) | 39 | 57 | 55 | 65 |

| Tire Configuration | Dualaxial | Triaxial | Triaxial | Triaxial |

| Jaw Crusher | HD86 | HD98 | HD110 | HD125 |

| Maximum Feeding Size(mm) | 500 | 550 | 660 | 800 |

| Discharge opening range | 50-150 | 75-175 | 100-200 | 125-225 |

| Capacity(t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Vibrating Feeder | ZSW380×95 | ZSW420×110 | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B800×8.5m | B1000×9.5m | B1000×11m | B1200×11m |

| Side-opening Belt conveyor(optional) | B500×3m | B650×3.5m | B650×4m | B650×4m |

| Gensrt(optional) | 200KW | 250KW | 270KW | 400KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

Other Products You May Need

SEND INQUIRY

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Product Center

Product Center Get Latest Price

Get Latest Price