Overview

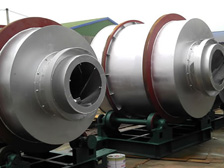

The fluorite, also called fluor, is a type of mineral consists of calcium fluoride. Before the artificial fluorite technology becomes mature, it is a kind of material used to make camera lens optical glass. The fluorite dryer usually works with the many types of furnaces like high temperature furnace in fluid bed, grinding coal powder spraying furnace and artificial coal furnace. It is also a type of rotary dryer made up of rotary drum, induced device, high speed scattering device, raising plate, self-cleaning device, transmission device, delivering device, hot blast device, reducer, supporting device and sealing device.

The fluorite dryer features reasonable and perfect design, reliable performance, advanced technology, high yield, low energy consumption, small area occupation and high mechanization level.

Features

1. Its high handling capacity, strong anti-overload capacity, high thermal efficiency and the coal consumption as low as 20% help reduce the drying cost.

2. The dryer exit has low temperature and high thermal efficiency.

3. Prevent the sticking problem of the interior wall of the dryer drum.

4. There exists no material blocking, discontinuous and uneven feeding and material returning problems; it decreases the load of the dust pelletizing system and overcomes the wind tunnel phenomenon happening to the traditional dryer.

5. Meet customers’ different requirements of materials’ particle size and water content after being dried.

Parameter

| Shell diameter × shell Length | Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell Length (m) |

Shell cubage (m³) |

Shell obliquity | Lifting blade form | Highest inlet air temperature (℃) |

Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

SEND INQUIRY

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Product Center

Product Center Get Latest Price

Get Latest Price