Overview

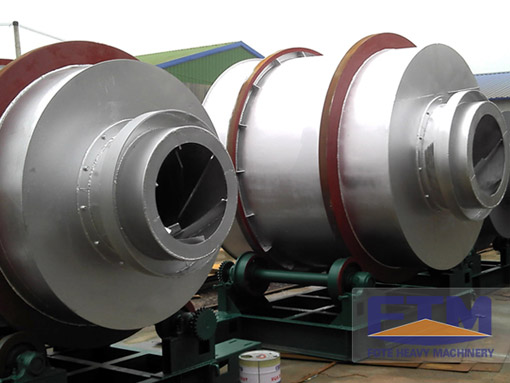

The river sand dryer or the river sand dryer machine made by Fote which is the leading river sand dryer manufacturer and supplier in China is famous for its fine river sand drying machine price and is researched and developed according to the properties of the river sand which is a common material that needs to be dried. The river sand dryer can realize high drying efficiency and good separation effect.

Features

1. The river sand dryer is made of the wear-resistant manganese plate which is 3-4 times more wear resisting than the common steel plate.

2. Materials consist of 15% moisture before entering the dryer and after being dried, they have only 0.5-1% water.

3. Compared with the traditional single drum dryer, the river sand dryer can reach a thermal efficiency of 40%.

4. It is fueled by the hard coal, soft coal, gangue, oil and steam etc and it can dry bulk materials, granular materials and powder materials with the particle size of 20-40mm.

5. The river sand dryer saves about 60% of both the floor area and the civil engineering investment. It can be easily installed.

6. The discharging temperature is no higher than 60℃ which makes the finished materials able to be stored in the storage bin without the necessity to be cooled in the cooling shed.

7. The temperature of the outer drum is also no higher than 60℃ and the temperature of the waste gas is lower than 120℃. The service time of the bag type dust cleaning apparatus can be prolonged more than 2 times.

8. The coal consumption of the river sand dryer is one third of the single drum dryer and it only consumes less than 9kg coal per ton. The sand dryer can save 40% of the power.

Parameter

| Shell diameter × shell Length | Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell Length (m) |

Shell cubage (m³) |

Shell obliquity | Lifting blade form | Highest inlet air temperature (℃) |

Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

SEND INQUIRY

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Product Center

Product Center Get Latest Price

Get Latest Price